Solar Tinker Toys – Illustration, Tom Miller

Solar Tinker Toys – Illustration, Tom Miller

Chris DeBone is Managing Partner of E-Gear LLC and co-founder / President of the Distributed Energy Resources Council of Hawaii (DERC). Prior to joining DERC, Chris was past president of the Hawaii Solar Energy Association (HSEA) and has been heavily involved in Hawaii energy policy. He has over 20 years of business operations, management, sales and marketing experience.

Editor’s note: This interview has been edited for clarity and length.

Tom: (Tom Miller – Creative Director, BayWa r.e. Solar Systems; Editor – Solar r.e.view): So E-Gear has a range of products and they’re all very integrated. Can you talk about E-Gear’s philosophy when it comes to solutions design?

Chris: It’s a very simple concept: making products that aren’t currently available in the marketplace—or were not available in the marketplace at the time of development—that are designed to meet new interconnection requirements.

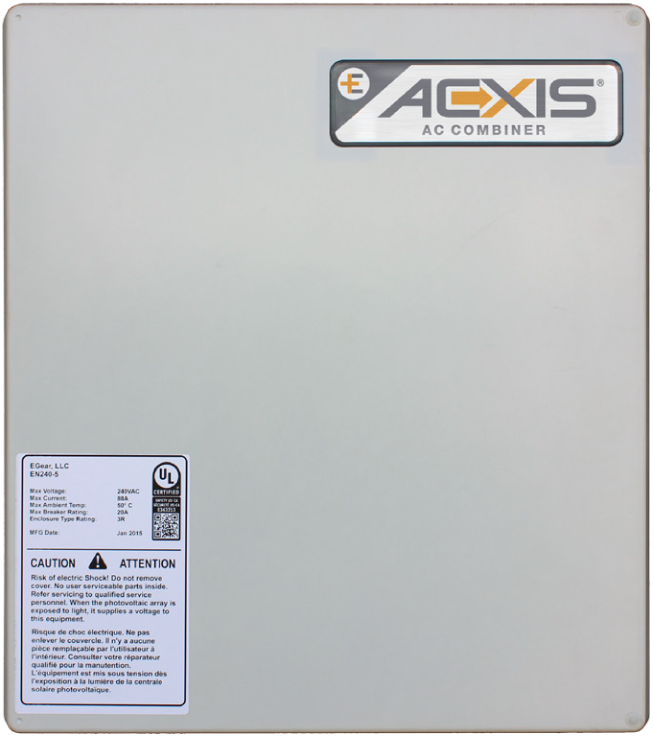

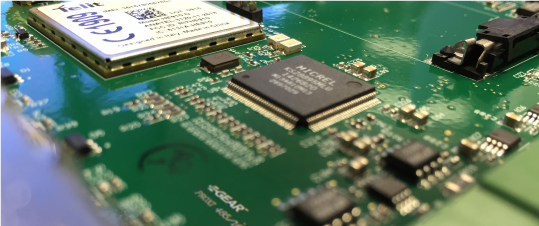

Photo, E-Gear

It all starts with the ACXIS box, our AC combiner box, which combines multiple microinverter strings together in one connection to a customer’s site. A lot of people are familiar with DC combiner boxes. But at the time, everyone was using home-load centers that you’d buy at Lowes or Home Depot to combine circuit strings. We had the notion to make an AC combiner box—like a DC combiner box—for the same purpose, but with improved functionality that can’t be found in a simple load center. It is also UL 1741 listed to keep the electrical inspectors happy.

Tom: Tell me a bit about where E-Gear came from.

Chris: The company was founded by its managing partners. They come from extensive backgrounds in solar installation, being an EPC for ten years in hot markets. E-Gear was created from an installer’s perspective of products that were needed in the market. The concept of the company is really to make affordable, and easy-to-use products, that save time and money for installers.

Tom: So I’m not as versed in the technology as many in the BayWa r.e. team. When you say that you “create products that meet new interconnection requirements,” can you explain that a bit more? Requirements are so variable and are continually updated. How do your products adapt?

Chris: Evolving out of our ACXIS box—our first product—we added an energy management controller, an EMC. This is a hardware and software platform housed within the ACXIS Box. The EMC allows for measurement of the home load or business load. Either residential or commercial. Three-phase or single-phase. And because, up until then, most customers were left in the dark as to their consumption, we designed the energy management controller inside the AXCIS box to also measure consumption. This is measured alongside production, and is agnostic of anyone’s type of inverters.

So it can measure, manage, and is retrofittable, on existing systems, or installable on new systems. With the changing interconnection landscape, it was taken one step further with the energy management controller that now has information about the production and consumption of the property and can now manage energy storage. So energy storage has unlocked the ability to have the PV system installed under just about any energy requirement out there. If you’re allowed to export, you can, if you can’t export, it won’t. If you want to export during certain times, you can do that. So it allows you to change with interconnection requirements and new tariffs really quickly.

Tom: So could it also be considered a risk-management tool, depending on what happens with requirements in your location?

Energy Management Controller – Photo, E-Gear

Chris: Yes. For example, if you install an energy management controller you can always add storage at that time, or down the line, to manage your energy behind the meter based on any upcoming tariffs or changes.

Tom: So I imagine you have good insight into how the utilities view storage in Hawaii. Can you talk about that a bit? And maybe apply it more broadly to the US?

Chris: Overall, I think utilities are still trying to find out where energy storage fits into the system. In fact, I’d go one step further and say that this is an international question as well. Countries and states are looking at how energy storage can, and should, be used within the grid. And then you can start to look at how this affects different ratepayers and cost causation.

Tom: But it has the potential to solve a lot of problems too, right?

Chris: Distributed energy storage can solve many more technical issues than centralized energy storage, regardless of where you are in the world. The utilities are trying to figure out the best ways to size storage and the solar industry is trying to entice the utility to go where they think the utility should be.

There’s room on the grid system for storage to be included everywhere, from the generation plant to the edge of grid. But to truly solve the problem of saturation, as solar continues to carve out more and more generation across the country, energy storage at the edge of the grid—distributed—can solve every issue of central storage, in addition to the secondary circuit issues. Voltage, real v. reactive power, frequency. And non-wire solutions.

So when you look at all the different things that energy storage can do from the utility’s perspective, you gain much more value the further down toward the edge of grid you go. That’s becoming clear to everybody. But what the utility’s role is in that is still out for the jury to decide.

Tom: I watched a video today that talked about flexible capacity and peak generators. Can you talk about storage’s role in those?

Chris: E-Gear believes that aggregated, edge-of-grid energy storage can morph into various types of grid services. Peaker plants; system level; circuit level; increased hosting capacity. Demand response is now becoming a topic of how batteries can play a role in exactly what you asked about—flexible load and offsetting the need for peaker plants to start up.

One of the technical issues now is that because energy storage is so fast the idea is floating around of integrating synthetic inertia into batteries so that they can react as traditional power plants can do. Because there’s very little ramp rate. Batteries just turn on and turn off. They’re so fast now that you have to put algorithms in there so it can act like it’s a peaker plant. It’s an interesting dilemma.

Tom: That’s really interesting—artificially creating something that’s not there.

Chris: Yeah! There’s no inertia in the battery—it’s pretty much instantly on and off. They can react, for example, as fast as frequency response in five cycles or less. Immediate power. So when you have an edge-of-grid energy storage system—that’s also capable of doing demand response—how to fit the capabilities of advanced energy storage into a demand response program has its challenges. Because it can do so much.

It’s almost too fast to just take care of the demand side of the meter, which is traditionally what a demand response program does. It’s just load modification. It’s turning off the pool pump. It’s turning on the water heater. Well, energy storage allows the customer’s habits to not change at all. There’s no inconvenience to the customer because the battery will be there to drop, or reduce, the load at that station without affecting anything inside the home.

Tom: I’ve read about monitoring systems that can identify an appliance’s unique electrical signature, which allows for monitoring on a per-appliance basis. Is E-Gear looking at this?

Chris: We’re familiar with it. We’ve tested it and we haven’t seen the results that we would expect, at the speeds we would expect. We currently do it on a device-by-device basis. Our controller has a ZigBee device built into it. So you can put ZigBee plugs on any device in the home and get actual data from the device itself. And it also gives you the ability to automate those. If it’s a pool pump, you can see exactly what the pool pump is doing, and also turn it off remotely as a side-benefit. So the flexibility in this case negates the reason to have the other technology. But it’s getting better and customers do like to know where their energy goes.

Tom: What are some of the changes that you’re seeing on the policy front, as it relates to storage?

Chris: Energy storage is getting customers net metering without having to export to the grid. So from an interconnection, policy perspective, it’s really replacing net metering in most places. But now there’s news that Nevada is bringing net metering back.

Tom: What should policy address sooner on the storage side? What should contractors be advocating for?

Chris: Well, I would say that something energy storage should allow—from a policy perspective—is expedited interconnection. Because it has less impact to the grid. Traditionally, a utility would put up studies and fees, and studies and fees… That’s what was in their bag of tricks. In this case, as energy storage is able to manage the power at the point of common coupling, and have a lesser impact to the grid, that should equal more expedited, and less stringent, interconnection.

Tom: How should contractors be talking to end-users about their storage options? What are some key points?

Chris: It depends on the region. For most regions, energy storage is often narrowly targeted for energy backup. That’s what gets most consumers excited about it: that they can use or store solar energy in case of a grid outage.

In other areas of the country, you can stack that value on top of additional savings due to tariffs that don’t give retail rates for exports, or disallow export altogether. But those two values compete with each other. So you have to first figure out what is the primary motivation for the end-use customer. Are they looking for emergency backup? If so, what is that safety worth to the customer? Then the customer has a value proposition they can review. Clean, renewable power on standby, for example.

Tom: What about energy savings?

Chris: From the standpoint of additional energy savings, it needs to be on a time-of-use program. Or a program where export is at a lower rate than retail rates. Then you have a monetary reason to do that.

But also once you’ve defended the value proposition for storage in the first place, some customers decide they want both—backup and savings. And the E-Gear system has been designed to give the customer a lever that they can leverage between the two. So they can either have the battery discharge on a daily basis to a very low state of charge, which will give them the most self-supply within their home—less export to the grid—or have it at a very high state of charge, and keep it at full, for security. But there’s always a battle between security and savings.

Tom: So we’ve covered some of this already, but run through your take on what solar contractors should be thinking about, in terms of storage, in the future. And maybe you can break it down to what’s going on now, then and what you anticipate seeing in two to five years. And maybe ten years out.

Chris: I think it’s important for solar contractors, today, to start thinking of themselves as energy contractors.

Our industry is moving toward the energy business and out of the pure-play solar business. For the installers willing to take on that challenge, right now is the time to make the decision to stay a solar contractor, or get into the energy business.

Also expect to see more battery systems deployed with renewable energy. So, solar contractors in the next couple of years should be learning about controls; algorithms; CT wires, current transformers; low voltage code; how do you install communication cable along with traditional solar electrical wiring? And be prepared for storage end-production to have more market share moving forward.

Tom: That kind of runs counter to a lot of what I’m hearing: about how solar technology is going to get simpler. You’re saying there’s more complexity and specialization coming down the pike.

Chris: Solar was tinker toys. Traditional solar installers—what we consider pipe and wire—will need to transform their system-commissioning skills.

Tom: Okay. What about in 20 years?

Chris: Nah! [Laughs] I don’t want to speculate. Magic 8-Ball and all that…

Tom: If we’re going to require a whole lot more specialization, what should contractors do to keep up? If they only had fifteen minutes a day to read through stuff, what would you recommend? What filters should they use to get the most out of their time spent?

Chris: I would probably say, go to trade shows. Meeting with the vendors and spending time with the technology is some of the best time spent. From my personal view of that question, to keep up with technology on a daily basis you get a lot of noise. There’s so much slide-ware and vapor-ware.

Take the fifteen minutes to keep up on daily news and events. But getting away, and going to energy, solar, and battery related trade shows—where you get to see the products and talk to the vendors—is worth doing once or twice a year.

Tom: Last question: what is the big outlier, that nobody knows about, that’s going to change everything?

Chris: I have an answer for that!

Tom: Oh, boy! I’d love to hear it!

Chris: It’s what we truly believe. Aggregation. It’s taking what was once a plethora of uncontrollable, distributed generators and turning them into distributed energy resources.

Tom: Okay. So lay that out for me.

Chris: There’s a big difference between DG (Distributed Generation) and a DER (Distributed Energy Resource). And the sooner you can add devices to renewable energy installations that capture production, consumption, load, voltage, data, etc., and whoever can install devices that capture data that is not necessarily captured by the utility—and can roll those into an aggregated fleet of renewable generation—will have a lot of value on their books in the future.

The solar industry has, historically, had a high cost of acquisition. You sit down at the kitchen table, sell a device, get paid, and then find another. But those who can aggregate those devices, and have some controls to turn them from an uncontrollable-state into a controllable-state—under your umbrella—will have the first opportunity to participate in upcoming policies.

These are policies that multiple states, and nations, are pushing: programs that incentivize customers to become part of the larger group of generation plants replacing fossil fuels. But the first step is aggregating your fleet of assets.

Tom: Are you talking about the ability to monitor clouds passing over an array and transfer that information to the utility? In order to ramp power? Or something else?

Chris: Those are smart meters. Smart meters only measure power and energy at the meter. What we need is a brilliant meter that tells you how much is solar—controllable or non-controllable generation—and how much is load. How do you subtract generation from load to show what the net load would have been? Smart meters can’t do that.

Tom: So build out the idea of what aggregating these assets will do a bit more.

Chris: Some of E-Gear’s dealers have taken it upon themselves to not necessarily install a battery storage system on every install. But they install the E-Gear energy management controller on the site—as a pure value-add to the customer. Then the customer can look at generation and load and see what their energy use is, compared with generation on a daily basis. So then they’re not surprised when they get their electric bill.

That installer—with the EMC information they’ve installed—has an interface with which they can track all of their customer’s device installations. This means they can go back later and offer energy storage as a retrofit plugin, and have all the data to analyze how much energy storage they need. It’s just a simple addition to a PV install today that will create benefits in the future.

Tom: Got it. So the contractors are able to collect a lot of data about their installs to leverage later, whether it’s with the homeowner or other parties.

Chris: Yup. Once they have smart inverters tied to it, and/or energy storage, that solar installer now has a fleet of these under their umbrella, and they can turn around and talk to the utility. They can talk about the services they can provide and what the value is for both the installer and the customer. Because they just became an aggregator of their assets. That’s what E-Gear is doing.

Tom: Okay! I think that’s a good place to stop. Thanks for taking the time to talk with us today.

Chris: No problem! Thanks for the opportunity.