There is a commonly held belief that if two PV module connectors fit together, then it is okay to connect them. This belief is incorrect.

In fact, coupling two PV wire connectors that aren’t UL listed for the application can lead to significant problems — either on the day of installation or at some point down the road. In this article we’ll go into detail on what to consider when mixing connectors in an application, but let’s first examine what happens when two connectors are mated together.

Making the Connection

It sounds like a story we’ve all heard before, but with a twist: when male and female connectors are properly joined, a spark of electricity can pass through the two as if they were one continuous wire.

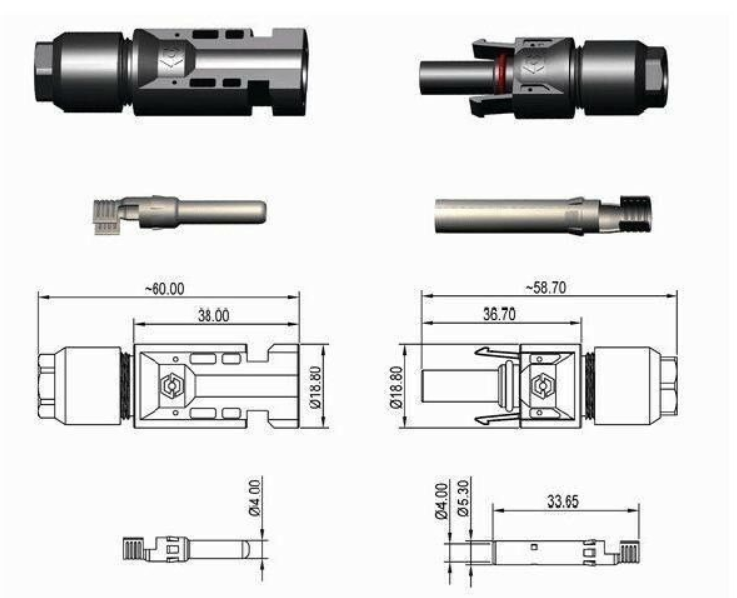

When these two connectors are joined, there are plated-metal contacts carefully designed to nest right against each other once clicked into place. These two metal plates create secure and conductive points of contact between the module and whatever it is being connected to. Surrounding these conductive plates, are:

- housings that secure the connected length of DC cable to its respective connective plate

- insulation which ensures the points of conductivity are protected and remain in place

- clipping mechanisms which secure the connection and protect the point of connection from the elements

Connector manufacturers perform extensive testing to ensure this connection remains steady and conductive for the anticipated life of the connection (25 years in the case of most PV modules). The best connector options have male + female housings that reliably snap together in an error proof way, protect the connection point from the elements, maintain the connection under strain, and can be disconnected and reconnected multiple times.

What issues might arise from mixing connectors?

Some things to keep in mind when considering mixing connectors in an application.

Broken UL Listing for the Assembly

Module male and female connectors must be UL together-listed for safe interconnection. Any connection that doesn’t meet this standard will interrupt the UL listing for the entire PV assembly.

Some connector manufacturers have gone so far as to describe their connector options as “MC4 Compatible.” Beware! There is no such thing as an “MC4 Compatible” connector. (This goes for any off-brand “compatible” options for other widely available connector types.)

In cases where one of the two connector manufacturers will provide a letter of computability with another connector, it is important to get written approval for the application from the second connector manufacturer in question.

Product Warranty / Insurance Liability Implications

Under extreme circumstances, a PV assembly with broken UL status may not be covered by insurance and product warranties. In a worst-case scenario, all affected property could fall under the installer’s liability if the array be involved in an insurance claim.

Issues that may arise

- Broken UL Listing for the Assembly

- Product Warranty / Insurance Liability Implications

- Less Consistent Point of Contact

- Less Durable Point of Connection

Less Consistent Point of Contact

All manufacturing processes involve a range of tolerance. In the case of connectors, male/female connectors from the same brand have specific manufacturing tolerances that ensure components on either extreme of the range will work together without issue. This ensures one can plug and re-plug connectors and know they will function properly each time the connection is made.

However, when connectors from different brands are used, the allowable tolerance between the male/female nested conductive plates has not been tested for compatibility or durability. This is a problem because even in cases where conductive plates are less than a hair’s width further apart than tolerance allows, micro-electrical arcing in the resulting gap may cause premature device wear, and lead to costly site visits for repairs.

Less Durable Point of Connection

For connectors not UL listed together — even in cases where a connection feels solid — the connection may still degrade over time. This degradation may occur because of repeated connecting and disconnecting, micro-arcing, particle (water or dirt) ingress, or metallurgical incompatibility.

This is an important point because in cases where an installer is on-site, servicing a component on either side of an incorrectly paired connection, any of the following may occur:

- it may prove difficult to disconnect two improperly mated connectors

- improperly matched connectors that nest properly the first time may not have the same predictable performance on subsequent disconnects/reconnects

- the previously well-performing point of connection may be impossible to reestablish after a mismatched connector pair has been disconnected and reconnected, even in cases where the connection seems physically solid

What is the best way to connect two connectors from different brands?

Transition whips are the best option in most cases. If the two connector brands are widely available, various manufacturers offer PV Connector transition cable whips with brand-specific connectors at each end.

In cases where one of the connector brands is not widely available, your module distributor needs to work with the module manufacturer to have connector whips provided. (Note: This will be an additional cost and should be considered when quoting out projects with less common connectors, especially in cases where MLPE will be included.)

The transition whip is an acceptable solution for most applications where connector mismatch is an issue. Different manufacturers have different guidelines for addressing module connector mismatch with a transition whip. This Application Note from SolarEdge is a good example of the guidance manufacturers should provide on this topic.

SolarEdge and other MLPE manufacturers will also sometimes offer to build their products with different connectors upon request, but MOQ and lead times for this path may be high, and not all PV connector types are offered.

The value of brand standardization on widely available PV DC connector options

The brands most attuned to this US-wide market requirement —like LG Electronics— have decided to standardize their DC connector across all lines of USA-bound production. These brands believe a widely available DC connector option is essential to the safe and reliable deployment of their product.

Choosing to standardize on widely available connector options (like MC4, in the LG Electronics example above) makes it easier to ensure that mismatches are not identified for the first time in the field — especially under the worst circumstance: by a savvy inspector/insurance investigator.

If a brand has not committed to market-wide connector standardization, it’s critical to check the connector match for each system design. This is especially true when working with MLPE. Anytime there is a new SKU on either side of the module/MLPE pair, module connectors and cable length should be considered.

Pick a distributor that keeps an eye on this issue

BayWa r.e. Solar Systems works closely with our vendor partners to ensure they understand why connector choice is so important.

Our webstore specifies which connectors are included with the products we offer. Whenever possible, we specify MC4 module connectors to match our most readily available MLPE options.

In cases where this is not possible, we work with our vendor partners to procure transition whips that have the manufacturer’s connector-of-choice on one end and a more widely available option on the other end.

Choosing a distributor that pays close attention to this issue will help ensure that your installations don’t encounter any of the issues related to connector mismatch.

***

Have any questions? Reach out to our Account Management Team. We are happy to guide you in finding the appropriate equipment.