Tom: Hi. Thank you all for taking the time today. Could you please both introduce yourselves and your role in development of this product?

Eric: My name is Eric Hafter and I’m the president of Sustainable Technologies. And we’ve worked for many years with Jack Patton on products for the solar industry and for other industries. Together we invented the Facet roof-mount system, originally in 2007, and now we’ve introduced our Gen2 version of Facet.

Jack: Hi. I’m the Executive VP of Engineering and inventor of the Facet product.

Eric: [Laughs] I think Jack is a little reluctant to say things about himself! But Jack developed two, rail-free based residential solar racking systems. The latest one, a couple of years ago, we sold to one of the premier solar racking manufacturers. Jack has also produced entire commercial racking solutions, which we also have the patent to. In addition, Jack has designed and built solar panel manufacturing facilities. So, a long history in developing products in the solar space.

Tom: In 2007, was the Facet developed as a response to any particular need that you saw? What was the genesis? Did the idea come out of a project you were working on?

Eric: That’s exactly how it came about. In 2007, with the company that Jack and I were working with before, we had built the Raley’s grocery store system in Lincoln, California. The method for installing solar racking at the time included, literally, chopping big holes in the roof, removing the material, removing the roof decking underneath, finding the truss structure, drilling into it, and attaching a very rigid attachment to the truss structure. And then modifying all of the roofing components that you’ve excavated, reassembling them, and putting on top of that a very large, very expensive, roof flashing component—which is sometimes referred to as a layer cake—along with liquid sealants, hose clamps, etc. Each hole was costing about $140 per location.

And that was standard in the industry at the time. And as builders, we said, “There’s got to be a better way.” And so Jack and I did a detailed investigation, looked at what are the structural capabilities of the roof structure itself—not just the building structure, but the actual structural elements of the roof—and realized that we could do something that would allow us to install a roof mounting device that was very strong without having to open the roof, or having to work from below the roof, at all.

Essentially, everything good happens from above the plane—you can dramatically reduce the amount of time, and therefore expense, of installing roof mounts. So it came from real world experiences. We just realized we could do something much better, faster, and less expensive.

Tom: I’m curious, is it part of your business model to create new products in response to needs that you see?

Eric: Yes it is. As a contractor, Enable Energy [Eric’s installation company] is building with what we think are the best, fastest, and least expensive products. But when we see something that could be done better that becomes the genesis for the next product Sustainable Technologies develops.

Tom: Take me through the process of developing a product. From the initial idea to final product?

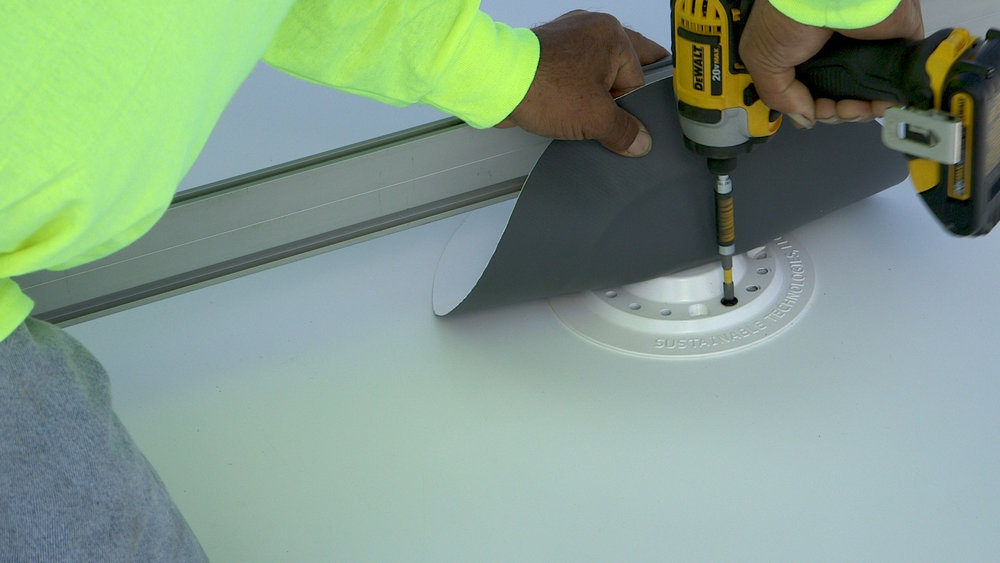

Install roofing or tek screws as required per structural engineer instructions. Photo – Tom Miller

Install roofing or tek screws as required per structural engineer instructions. Photo – Tom Miller

Eric: Building a solar system requires a lot of repetitive motions. This means that installers are performing the same process hundreds or even thousands of times. And if you’re doing anything a thousand times—if you can shave off one minute—that’s a significant change in your overall cost. I started in solar in ’93, and it’s been a non-stop push for lower cost all the time. So during the installation process, we do detailed time studies of each and every step and ask, “How can we make it better?” And what Jack has done repeatedly is that when we identify something that can be done better—and better means, stronger, faster, less expensive, less strain on the installer, a better outcome with regard to waterproofing, etc.— that becomes the flag that notifies us that there’s potential to find a better solution. And this is where Jack’s genius comes in. We posit a problem and Jack is able to look at something and visualize a solution.

Tom: Jack, will you take me through that process? Are you doing drawings? Are you working with a local manufacture on prototypes? What’s the process?

Jack: A little bit of everything there. But first, I’d like to add that there are also projects where there’s no “right” product for the job at all. This also can spur product development. And, actually, the Facet was originally designed because we were the ninth company brought in to try and put solar on top of the Staples Center.

The project was very challenging because there was no working from the underside of the roof—the roof is 92 to 120 feet in the air! And there was no opportunity for us to open up the roof from the top because the building owners absolutely refused to allow us to do any cutting into the roof. The final challenge was that the building is 110 feet high, with no parapet, so the wind forces on this building and roof are tremendous.

So it was solving that particular installation issue—where we needed something that we could work on from above the roof—that was not going to cause problems and be very, very strong. That’s what led to the actual Facet design.

Tom: And the design process?

Jack: As far as design goes, first of all, there’s the research. Is there a product out there that could do the same thing we need? If not, what are the criteria that we need to design to? Once we have that, then I go into a 3D, solid modeling of the product. And we go through iterations there. We go through FEA—Finite Element Analysis…

Eric: That’s where you determine how a product is going to behave structurally, without having to go through extensive physical testing. You do the testing in the computer.

Jack: Yeah. Then you ask, “What’s the manufacturing cost?” If everything looks good, and it seems promising, you build a prototype, test it, and if that is good, then you start looking at the manufacturing side of it.

Tom: Are you building the prototype yourself? Are you working with a local company?

Eric: It depends on the project. With the original Facet prototype, we went to a metal shop and we had them weld together a concept. We did additional prototyping at UC Davis. They have a very high-end 3-D printing lab, and we were able to print test components using different materials. Then we could evaluate them physically and see how to make them better. We’ve worked with UC Davis for a number of years now.

Tom: Do you have any data on time savings associated with the Facet?

Eric: From a logistics standpoint: the Facet ships at 1,000 units per pallet, 28 to a box. So it’s very simple and easy to put these on the roof and distribute them.

From a training standpoint, when we install these, we’ve designed them specifically so the installers do not have to do precision layout. They can assemble the Facet, along with the rail system, before putting any of the screws into the deck. That’s important because all the other products in the space require—in advance—a team to go and do a precision layout and mark exactly where the roof mounts go. Because the Facet can be installed with the racking before fixing it to the roof, that increases flexibility when you get up there. It’s very easy to adjust, so that saves time. From an installation standpoint, it’s very simple, very intuitive, and is completely in keeping with standard roof patching methodologies. Finally, it takes a person unfamiliar with the product about five minutes to learn how to install the Facet. Once they’re familiar with it, once the muscle memory sinks in, complete installation, including rail assembly, takes about four minutes per Facet.

Tom: How about testing?

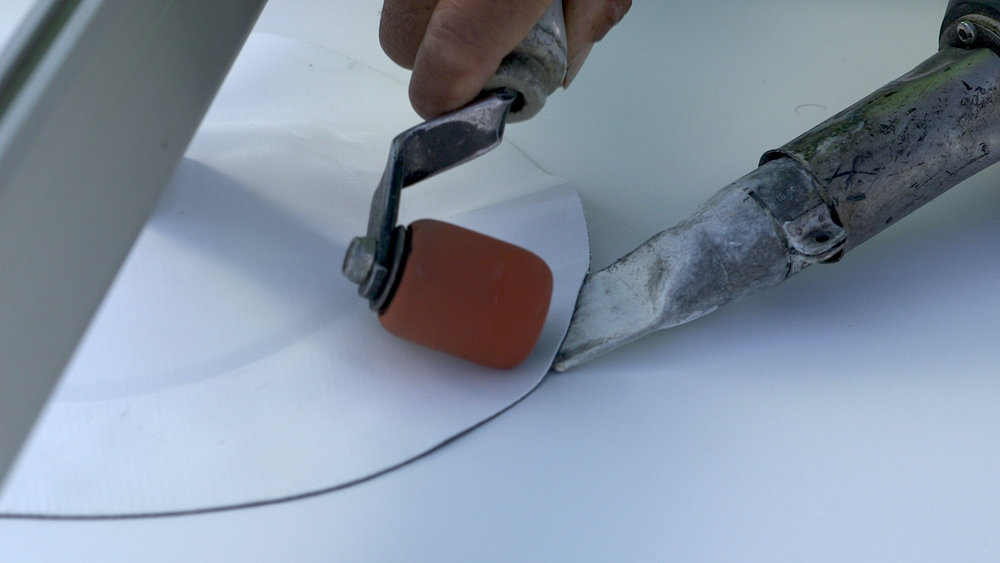

Heat welding the flashing membrane skirt directly to the roof membrane. Photo – Tom Miller

Heat welding the flashing membrane skirt directly to the roof membrane. Photo – Tom Miller

Eric: We do a lot of work with GAF, America’s largest roofing manufacturer. They have a very significant R&D facility in Parsippany, New Jersey. At their amazing facilities they perform every conceivable test you can imagine. Including a device that will shoot at 2-inch ice ball at 80 miles an hour.

When we first showed them Facet, they got very excited because they also saw this as a way to enhance their roof warranty because Facet installation is perfectly in keeping with their preferred flashing approach. So GAF put Facet through an exhaustive study, and provided a lot of support. After they put the Facet system through the ringer, GAF issued a strong endorsement letter, which is available on our website. One of the tests that we performed is we took a Facet and put it in a column of water with blotter paper underneath and left it for a year. Blotter paper will show the tiniest drop if there is any leak. And after a year’s installation, it was bone dry.

Tom: Jack, was that your idea?

Jack: [Laughs] We’ve actually done other tests, too. I put it under 45 psi of water pressure, with no indication of leaking. It was our intention to have, not only the strongest, but the best waterproofing products out there. And we greatly exceeded our goal.

Tom: Are there other applications, besides just solar applications for the Facet?

Eric: Yes. Windscreens. Process piping and electrical piping. You can attach it to anything that goes on the roof. Residential contractors are using Facets in electrical rooms to install straight onto the walls. They want to have a little leeway, and have it be simple and strong, so it’s a great solution for that. The current Facet is good for many applications, but we’re also looking at different sizes for very large air-conditioning units.

[Grant Ferrell, CFO, Enable Energy, enters the room and jumps on the line.]

Grant: Hi, Tom. Grant here. I want to mention that we’re also developing a family of attachment products to go along with the Facet. There are so many great racking companies out there, and we see our role as assisting in improving the integrity of those racking products through the attachment products that we’re creating. In 3 to 5 years, it’s our hope to have 20 to 30 attachment-like-products that complement existing racking systems that are out there.

Tom: Okay! Well, those are all my questions. Nice to talk with you for a second at the end there, Grant. I appreciate you all taking the time today.

Eric, Jack, Grant: Thanks for the opportunity!