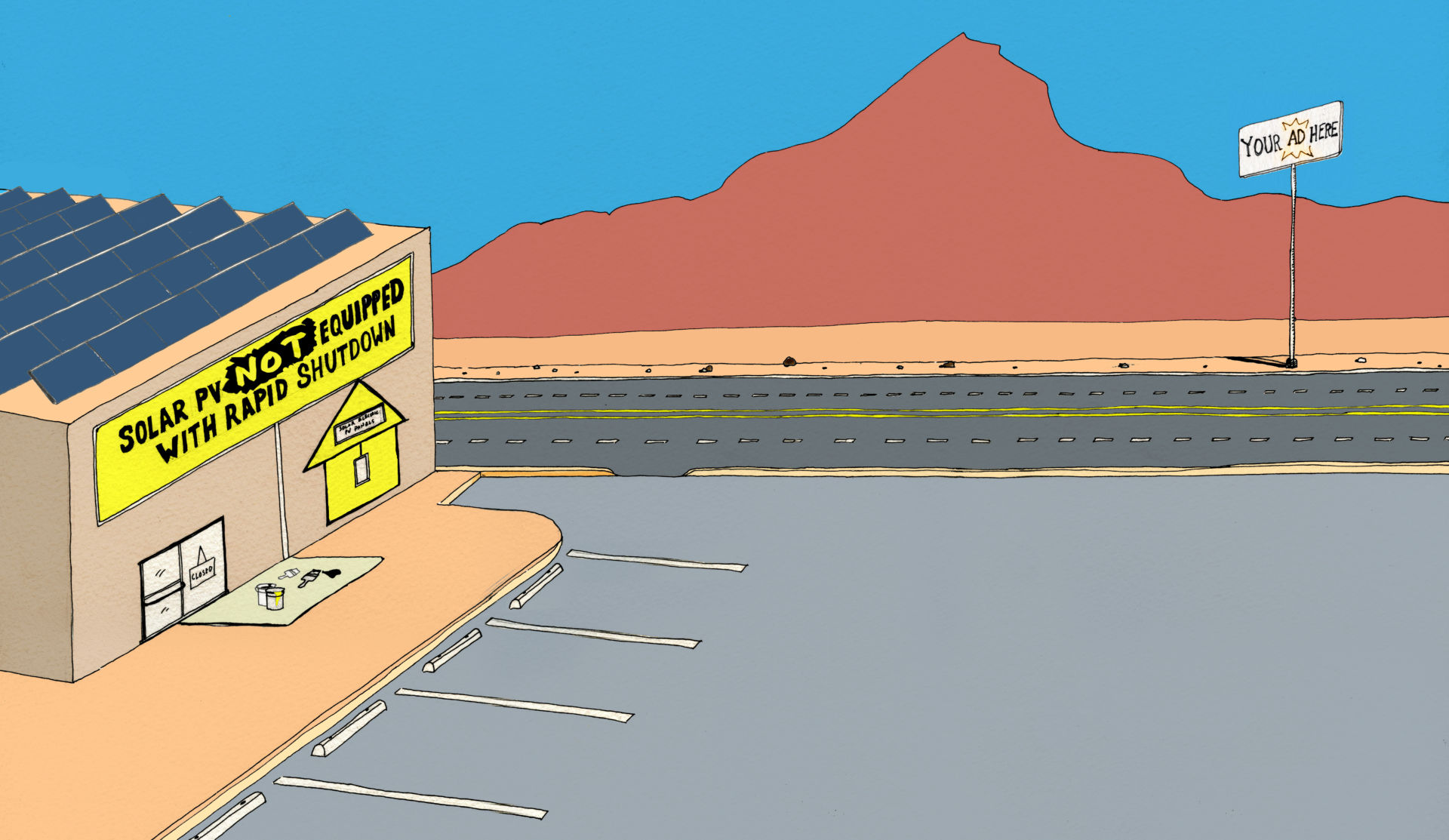

Illustration – Tom Miller

The previous update to the National Electrical Code (NEC 2014) introduced meaningful rapid shutdown requirements, but the impact wasn’t felt evenly across the solar industry.

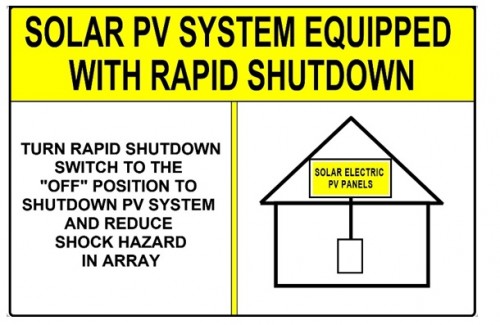

Intended to increase safety for firefighters working near an energized PV system, NEC 2014 required the ability to reduce system voltage quickly, leaving no wires energized more than 5 feet inside a building or 10 feet from a solar module array.

The response from residential installers was the increased adoption of module-level power electronics or the addition of a purpose-built combiner box between the array and the inverter. On commercial flat roofs, compliance with NEC 2014 was a cinch. As David Brearley notes in SolarPro Magazine, designers “simply need to locate three-phase string inverters on the roof within 10 feet of the array.”

NEC 2017, however, adds new rapid shutdown requirements that may prove challenging for commercial installers. In the residential market, installers have been preparing for the transition to NEC 2017 for some time and have a variety of compliant solutions to choose from, including microinverters; software upgrades to module-level power electronics; or simple add-on devices. In contrast, many commercial installers have turned a blind eye to the new NEC 2017 requirements, since the 2014 code did not require their attention.

This article will describe the changes in NEC 2017 relevant to commercial installations, the industry response thus far, the timeline for adoption of NEC 2017, and further changes under consideration for the next update to the NEC in 2020.

How rapid shutdown has evolved

NEC 2014 addressed two specific safety concerns for firefighters encountering buildings with PV systems on the roof: 1) DC circuits were often concealed from view and 2) a disconnect switch at the utility meter or the inverter did not de-energize these circuits on a sunny day.

NEC 2014 took aim at these DC circuits, requiring that circuits drop below 30 volts within 10 seconds after the inverter is disconnected from utility service.

However, a presentation at the Solar Energy Industries Association Codes & Standards Symposium in March 2018 pointed out some of the limitations of this approach:

- The 10-foot array boundary left room for interpretation, with some jurisdictions concluding that there must be a 20-foot boundary between module arrays.

- The 10-second requirement conflicted with smart inverter standards that instruct inverters to ride through momentary fluctuations in grid frequency or grid voltage.

- Finally, and most important, firefighters generally considered NEC 2014 to be an insufficient safety measure because it did not mitigate the risk of high voltage in and around the module array.

To address these concerns, NEC 2017 narrowed the boundary zone to 1 foot in all directions from the array and 3 feet inside the building. Circuits still must drop below 30 volts, but NEC 2017 provides 30 seconds for them to do so, allowing systems to satisfy rapid shutdown and low-voltage ride-through.

NEC 2017 also requires that PV circuits inside the module array drop to 80 volts within 30 seconds, unless the array has no exposed wiring or conductive parts and it’s more than 8 feet from any exposed, grounded electrical components—meaning it’s a building-integrated (BIPV) system. NEC 2017 also requires that products designed for rapid shutdown be listed according to a relevant industry test standard, such as UL 1741.

Industry response

After NEC 2014 took effect, equipment suppliers responded one by one with proprietary solutions to help their customers meet array-level rapid shutdown requirements. This time, however, the industry response has been more proactive and collaborative. The SunSpec Alliance, a trade organization pursuing information and communications standards for the distributed energy industry, led more than 30 companies to create an open communication signal that any rapid shutdown device can use to comply with NEC 2017.

The SunSpec Communication Signal for Rapid Shutdown Interoperability Specification, published in September 2017, establishes a protocol to transmit messages over the DC circuits between a master control device and a device in the module junction box.

SunSpec’s rapid shutdown communication protocol has two key advantages: 1) it enables plug-and-play interoperability, providing the ability to mix and match any one supplier’s rapid shutdown solution with another and 2) as an open standard, the SunSpec approach helps drive down cost and component parts count. As Chris Crowell notes in Solar Builder, the SunSpec communication protocol should quickly eliminate the need for a purpose-built combiner box to satisfy rapid shutdown requirements.

Timeline for adoption

NEC 2017 takes effect on January 1, 2019, but it’s up to officials at the state level to determine when the Authorities Having Jurisdiction (AHJs) must update to the latest version of the electrical code.

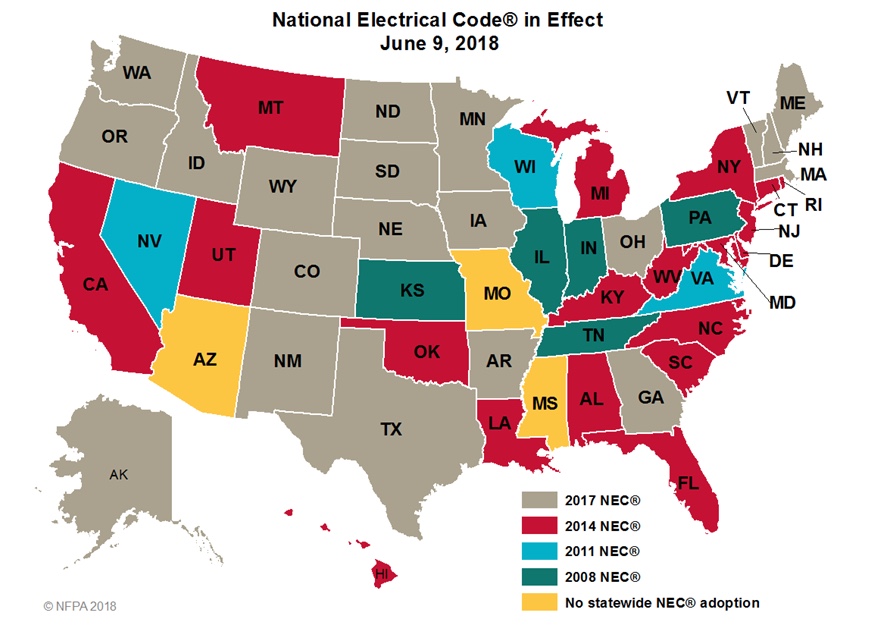

The National Fire Protection Association keeps tabs on NEC adoption on its website. Some states, like Colorado, Massachusetts, and Texas, have moved quickly to adopt NEC 2017, while many more have not.

As of June 2018, nine states, including New Jersey, North Carolina, Florida, and Utah, are in the process of updating to NEC 2017. Meanwhile, NEC 2014 continues to serve as the basis for the California Electrical Code, while NEC 2011 and NEC 2008 remain in effect in a handful of states.

This article will describe the changes in NEC 2017 relevant to commercial installations, the industry response thus far, the timeline for adoption of NEC 2017, and further changes under consideration for the next update to the NEC in 2020.

How rapid shutdown has evolved

NEC 2014 addressed two specific safety concerns for firefighters encountering buildings with PV systems on the roof: 1) DC circuits were often concealed from view and 2) a disconnect switch at the utility meter or the inverter did not de-energize these circuits on a sunny day.

NEC 2014 took aim at these DC circuits, requiring that circuits drop below 30 volts within 10 seconds after the inverter is disconnected from utility service.

However, a presentation at the Solar Energy Industries Association Codes & Standards Symposium in March 2018 pointed out some of the limitations of this approach:

- The 10-foot array boundary left room for interpretation, with some jurisdictions concluding that there must be a 20-foot boundary between module arrays.

- The 10-second requirement conflicted with smart inverter standards that instruct inverters to ride through momentary fluctuations in grid frequency or grid voltage.

- Finally, and most important, firefighters generally considered NEC 2014 to be an insufficient safety measure because it did not mitigate the risk of high voltage in and around the module array.

To address these concerns, NEC 2017 narrowed the boundary zone to 1 foot in all directions from the array and 3 feet inside the building. Outside of this new boundary circuits still must drop below 30 volts, but NEC 2017 allots up to 30 seconds after shutdown for them to do so, allowing systems to satisfy both rapid shutdown and low-voltage ride-through requirements without conflict.

NEC 2017 also requires that PV circuits inside the module array drop to 80 volts within 30 seconds, unless the array has no exposed wiring or conductive parts and it’s more than 8 feet from any exposed, grounded electrical components—meaning it’s a building-integrated (BIPV) system. NEC 2017 also requires that products designed for rapid shutdown be listed according to a relevant industry test standard, such as UL 1741.

Industry response

After NEC 2014 took effect, equipment suppliers responded one by one with proprietary solutions to help their customers meet array-level rapid shutdown requirements. This time, however, the industry response has been more proactive and collaborative. The SunSpec Alliance, a trade organization pursuing information and communications standards for the distributed energy industry, led more than 30 companies to create an open communication signal that any rapid shutdown device can use to comply with NEC 2017.

The SunSpec Communication Signal for Rapid Shutdown Interoperability Specification, published in September 2017, establishes a protocol for transmitting data and commands over the DC circuits; allowing communication between a master control device and a module level power electronic (MLPE) receiver.

SunSpec’s rapid shutdown communication protocol has two key advantages: 1) it enables plug-and-play interoperability, providing the ability to mix and match any one supplier’s rapid shutdown solution with another and 2) as an open standard, the SunSpec approach helps drive down cost and component parts count. As Chris Crowell notes in Solar Builder, the SunSpec communication protocol should quickly eliminate the need for a purpose-built combiner box to satisfy rapid shutdown requirements.

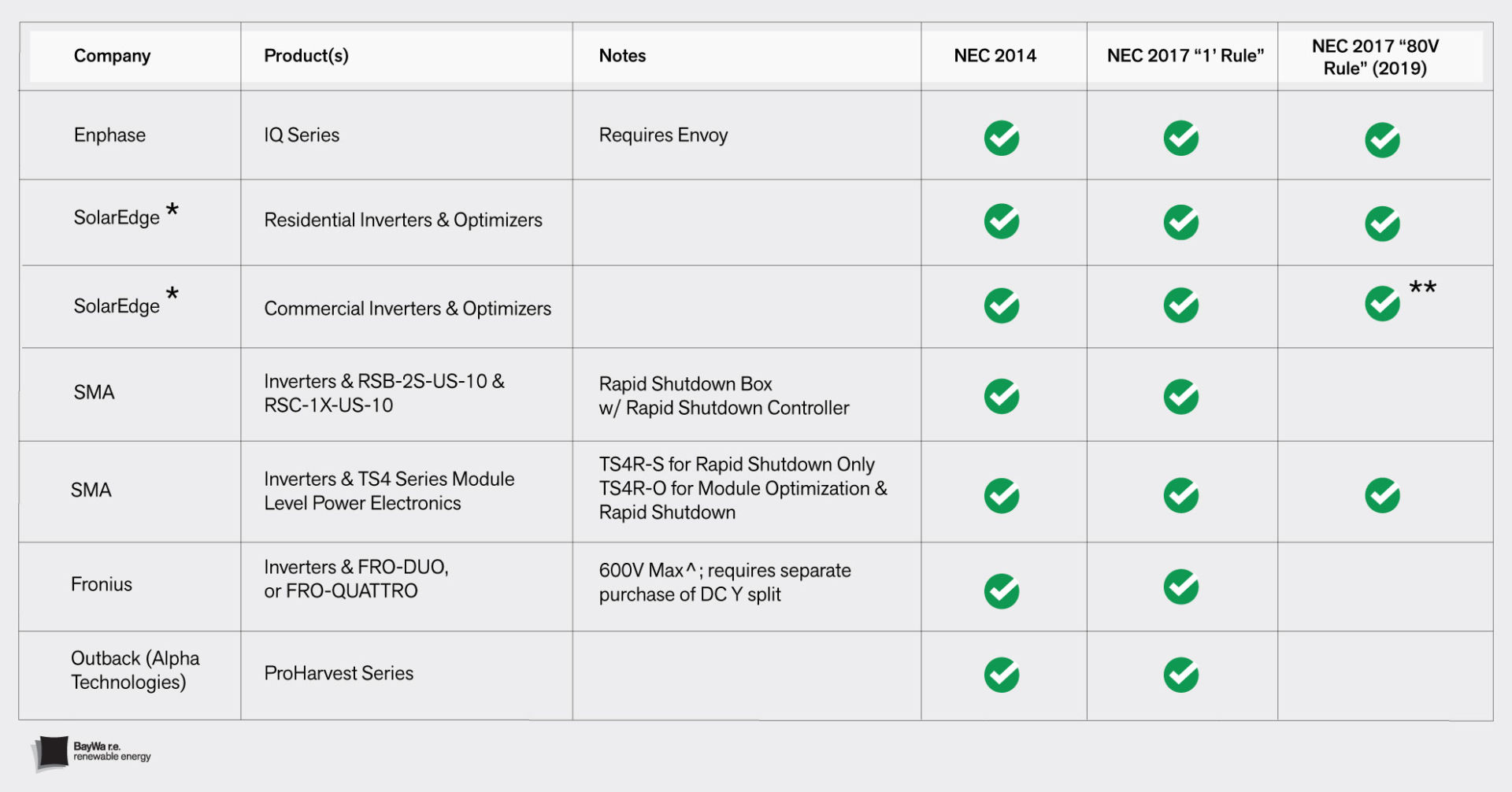

(Click table to expand)

* For earlier Inverter versions with manual disconnects, use SE-1000-RSD-S1.

**Note optimizer and module open circuit voltage to ensure compliance w/ “80V Rule” when using dual (series) input optimizers. Often the 800P is the best option for compliance

^ For 1000V applications, pair Fronius with a third party 1000V rated Rapid Shutdown solution.

Enphase Energy

Enphase microinverters comply with NEC 2014 and NEC 2017.

Fronius

Fronius provides two versions of its Rapid Shutdown Box, Duo and Quattro. Each requires the separate purchase of Y split DC Connectors for proper installation. Each has a max system voltage of 600V. Use either to comply with NEC 2014 and NEC 2017 “1’ Rule”.

HiQ Solar

HiQ inverters comply with NEC 2014 and the NEC 2017 “1’ Rule”.

SMA

SMA Inverters plus TS4R-S or TS4R-O MLPE comply with NEC 2017 “80V Rule.”

SolarEdge

SolarEdge Inverters plus Optimizers comply with NEC 2014 and NEC 2017.

- When specifying commercial optimizers for installation after 80V limit is in place, take care to choose an appropriate optimizer solution.

- The P800P – designed for parallel DC inputs – is likely the best currently available commercial option under these conditions (so long as module Open Circuit Voltage rests well below 80V).

- SolarEdge provides a Rapid Shutdown Kit for older single-phase inverters with manual disconnects.